About this document

This document is available for all employees via the project network and is approved for use. This document is regularly updated and the latest version is available electronically. Once printed, the document should no longer be considered to be the latest version. It may be distributed externally, for example to the ECO Aviation Fuel Development Ltd. as a controlled document. As such, the front cover should be stamped “Controlled Copy” in red, a copy number added and distribution records maintained.

The project environmental coordinator is responsible for updating and maintaining this plan. The original hard-copy of the document should be signed to indicate approval and filed in the project filing system.

If you have any enquiry relating to this plan, please contact the project environmental coordinator in the first instance.

| Revision | Date | Section/Description | Authorized by |

|---|---|---|---|

| 0 | 5.1.2006 | Issued for Review | BG |

| 1 | 10.2.2006 | Issued for Construction. Revised contents, section 4, section 5, Appendix A to E | BG |

| 2 | 3.04.06 | Revised contents, section 4, section 5, table 5.1, table 5.3, Appendix A | BG |

Contents

Page

Section 1 – Purpose

The purpose of this Waste Management Plan includes:

- –

- identifying the quantity of waste generation from construction;

Section 2 – Scope

The scope of this Waste Management Plan covers waste produced by Leighton Contractors (Asia) Limited during the construction of Permanent Aviation Fuel Facility.

2.1 Description of Works

The Airport Authority has awarded a franchise to ECO Aviation Fuel Development Ltd. to build and operate the Permanent Aviation Fuel Facility (PAFF) to provide fuel for Hong Kong International Airport at Chek Lap Kok.

The PAFF works to be executed shall include the design, construction, and commissioning, of the following major items:

Marine Receipt Facility jetty including foundations/piling, berthing and mooring dolphins, loading platforms, bollards, fenders, loading arms, pipework, and electrical and mechanical services and associated fire protection;

Tank farm including fuel tanks and ancillary pipework, foundations, earthworks, containment bunds, paving, drainage, fencing, mechanical and electrical services; and associated fire protection;

Under seabed twin piggable fuel pipelines from jetty to tank farm and from tank farm to the Existing Aviation Fuel System with connection to the existing submarine pipeline including cathodic protection, leak detection system and pig traps at the tank farm;

Modify seawalls and shore protection;

Utility services, including permanent and temporary storm water drainage systems, foul sewerage systems, water mains and ancillary water works, electrical supply, lighting systems, lighting masts, fire hydrant systems, fire-protection systems, pumping and filtering systems etc.;

Landscape works;

Buildings, including offices, transformer room, toilet, control room, workshop, pump room, switchboard room, laboratory and store.

Foundations, including piling as necessary.

Obtain all licences and approvals necessary for the construction and operation of the Facility

Section 3 – Waste Management Policy

This document sets out the waste management policy of Leighton Contractors (Asia) Limited to be implemented during activities associated with the design and construction of Permanent Aviation Fuel Facility in Tuen Mun, New Territories. The policy and Waste Management Plan is approved and issued with my authority.

It is our policy to provide sufficient resources and facilities for the implementation of effective waste management.

The objectives of implementing the Waste Management Plan are to:

i) reduce and minimize waste generated from the activities associated with the works while ensuring that the execution of project activities conforms with contractual and regulatory requirements;

ii) manage material and waste, including control and disposal, arising from the works for the project; and

iii) achieve the specific waste objectives and targets set by Leighton Contractors (Asia) Limited and reviewed from time to time (details of waste objectives and targets refer to clause 5.7).

The Waste Management Plan will be reviewed periodically by the project environmental review committee and revised if necessary to achieve continual improvement. The requirements of this plan will be communicated to all project staff who are required to diligently perform the duties that are assigned to them and to extend the understanding and acceptance of waste management policy to our subcontractors, suppliers and service providers.

As the project director, I require your active cooperation and participation to ensure that the Waste Management Plan becomes an integral part of the environmental management systems that will contribute to the overall success of the project.

Brian Gillon Project Director Date: 5th January 2006

Section 4 – Relevant Environmental Legislation and Guidelines

The Leighton Contractors (Asia) Limited shall comply with the following Hong Kong SAR ordinances and regulations, which cover, or have some bearing on, the handling, treatment and disposal of waste.

4.1 Ordinances and Regulations

4.1.1 Waste Disposal Ordinance (Cap 354)

This ordinance prohibits any person from using any land or premises for the disposal of waste unless one has been authorized by or has obtained a license from the waste-disposal authority, the Environmental Protection Department.

4.1.2 Waste Disposal (Chemical Waste) (General) Regulation, Enacted Under Waste Disposal Ordinance

This regulation has provisions to require any person who produces chemical waste to register with the Environmental Protection Department as well as to control the processing, storage, collection, transport and disposal of chemical waste. In additional, the regulation also provides for the licensing of waste collection, transport and disposal activities.

Chemical waste includes any scrap materials, or unwanted substances specified under Schedule 1 of this Regulation, if such a substance or chemical occurs in such a form, quantity or concentration that causes pollution or constitutes a danger to health or risk of pollution to the environment.

A person shall not produce, or cause to be produced, chemical wastes unless he is registered with EPD. Any person who contravenes this requirement commits an offence and is liable to a fine and/or imprisonment. Chemical wastes must be treated, utilising on-site plant licensed by EPD or have a licensed collector to transport the wastes to a licensed facility. For each consignment of wastes, the waste producer, collector and disposer of the wastes must sign all relevant parts of a computerised trip ticket. The system is designed to trace wastes from production to disposal.

This regulation also prescribes the storage facilities to be provided on site including labelling and warning sign. To minimise the risks of pollution and danger to human health or life, the waste producer is required to prepare and make available written emergency procedures for spillage, leakage or accidents arising from storage of chemical wastes, and provide employees with training for such procedures.

4.1.3 Land (Miscellaneous Provisions) Ordinance (Cap 28)

Inert construction waste may be taken to public dumps. The Land (Miscellaneous Provisions) Ordinance requires that a dumping licence be obtained by individuals,

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

or companies, who deliver suitable construction waste to a public filling facility. The licence is issued by the Civil Engineering Department. When public dumping of such material is required, Leighton Contractors (Asia) Limited shall apply for the licence prior to disposal.

4.1.4 Public Health and Municipal Services Ordinance (Cap 132) - Public Cleansing and Prevention of Nuisances Regulation

This ordinance has provisions on the control of the discharge of hazardous material to sewers and for the control of littering. The ordinance prohibits placing or throwing any solid matter, mud or waste into public sewers or drains and also placing those substances in a location where they may fall into public sewers and drains. The ordinance also has provisions to require the owner or occupier of the land adjoining any street or place that is situated near a public sewer to exercise measures to prevent obstruction of sewers and drains caused by soil and waste.

4.1.5 Dumping at Sea Ordinance

The Dumping at Sea Ordinance requires that dumping permits are obtained by individuals or companies who deliver dredged/excavated marine sediment to designated disposal sites. The permits are issued by Environmental Protection Department under delegated powers from the Director of Environmental Protection. The permit shall be applied for as required.

4.1.6 Air Pollution Control (Open Burning) Regulation (CAP 311O) Enacted Under Air pollution Control Ordinance

This regulation prohibits or restricts the open burning in or at any place what so ever of any kind of material that may evolve air pollutants unless one has been authorised or obtained a permit from the Environmental Protection Department.

Open burning means the combustion of materials of any type outdoors without an enclosure, where the products of combustion are not directed through a chimney.

Open burning for the following purpose is prohibited: a) The disposal of construction waste b) The clearance of a site in preparation for construction works c) The disposal of tyres; and d) The salvage of metal.

4.1.7 Waste Disposal (Charges for Disposal of Construction Waste) Regulation (Cap 354N)

This regulation sets out the details of the construction waste disposal charging scheme and identifies the Designated Waste Disposal facility (DWDF) for disposal of construction waste at landfills, sorting facilities and public fill reception facilities.

The regulation sets the disposal charges at $125 per tonne at landfills, $100 per tonne at sorting facilities and $27 per tonne at public fill reception facilities in order to fully recover the capital and recurrent costs of the facilities according to

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

the polluter pays principle.

The regulation requires the main contractor (of works with a value of $1 million or above) to make an application to the DEP within 21 days after of award of contract to establish a billing account. Once a billing account has been established the DEP will issue “chits” which will be used to record the disposal of waste at a designated waste disposal facility.

When delivering a load of waste to a designated waste disposal facility the waste hauler appointed by the account holder will be required to produce a valid “chit”.

4.1.8 Admission Ticket for Disposal of Special Waste at Landfills

Some waste will only be accepted at landfills with prior authorization from Environmental Protection Department under the Admission Ticket System. These waste include sludge/residue from sewage treatment plants, water works or industrial and commercial processes with a dry solid content of less than 30% but greater than 20% by weight for WENT & SENT, or greater than 15% for NENT, tyres and other wastes such as dewatered dredged material with a liquid content less than 70% by weight and contaminated material, etc. Admission Tickets are obtained by individuals or companies who deliver these special waste to designated landfill sites. The Admission Tickets are issued by Environmental Protection Department under delegated powers from the Director of Environmental Protection. The ticket shall be applied for as required.

4.2 Additional References and Guidelines

This Waste Management Plan has been prepared with reference to:

- (a)

- Waste Reduction Framework Plan, 1998 to 2007, Planning, Environment and Lands Bureau, Government Secretariat (5 November 1998);

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

| Department; | ||

|---|---|---|

| (g) | Code of Practice on the Packaging, Labelling and Storage of Chemical | |

| Wastes (1992), Environmental Protection Department; | ||

| (h) | A Guide to the Control on Import and Export of Waste (1999), | |

| Environmental Protection Department; | ||

| (i) | Works Bureau Technical Circular | No. 10/92, Provision of Refuse |

| Containment Booms in Reclamation Contracts Involving Public Dumping, | ||

| Works Bureau; | ||

| (j) | Works Branch Technical Circular 32/92, The Use of tropical Hard Wood | |

| on Construction Sites, Works Branch; | ||

| (k) | Works Bureau Technical Circular No. 2/93, Public Dumps, Works Bureau; | |

| (l) | Works Bureau Technical Circular No. 2/93B, Public Filling Facilities, | |

| Works Bureau; | ||

| (m) | Works Bureau Technical Circular No. 16/96, Wet Soil in Public Dumps, | |

| Works Bureau; | ||

| (n) | Works Bureau Technical Circular No. 4/98 and 4/98A, Use of Public Fill | |

| in Reclamation and Earth Filling Projects, Works Bureau; | ||

| (o) | Works Bureau Technical Circular No. 25/99, 25/99A and 25/99C, | |

| Incorporation of Information on Construction and Demolition Material | ||

| Management in Public Works Sub-committee Papers, Works Bureau; | ||

| (p) | Works Bureau Technical Circular No 12/00, Fill Management; Works | |

| Bureau; | ||

| (q) | Works Bureau Technical Circular No 19/01, Metallic Site Hoardings and | |

| Signboards, Works Bureau; | ||

| (r) | Works Bureau Technical Circular No 6/02 and 6/02A, Enhancement | |

| Specification for Site Cleanliness and Tidiness, Works Bureau; | ||

| (s) | Works Bureau Technical Circular No 12/2002, Specification Facilitating | |

| the Use of Recycled Aggregates, Works Bureau; | ||

| (t) | Environment, Transport and Works Bureau Technical Circular (Works) | |

| Permanent Aviation Fuel Facility (H2104) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No 33/2002, Management of Construction and Demolition Material | |||||||||||||

| including Rock, Environment, Transport and Works Bureau; | |||||||||||||

| (u) | Environment, Transport and Works Bureau Technical Circular (Works) | ||||||||||||

| No 34/2002, Management of Dredged/Excavated Sediment, Environment, | |||||||||||||

| Transport and Works Bureau; and | |||||||||||||

| (v) | Environment, Transport and Works Bureau Technical Circular (Works) | ||||||||||||

| No | 19/2005, | Environmental | Management | on | Construction | Sites, | |||||||

| Environment, Transport and Works Bureau. | |||||||||||||

| (w) | Environment, Transport and Works Bureau Technical Circular (Works) | ||||||||||||

| No 31/2004, Trip Ticket System for Disposal of Construction & | |||||||||||||

| Demolition Materials, Environment, Transport and Works Bureau. | |||||||||||||

| (x) | Memo Ref. (15) in FM PF/GEN/18.01 Pt.4 dated 22 December 2004 on | ||||||||||||

| “Enhancement of Trip Ticket System for Disposal of Construction and | |||||||||||||

| Demolition Materials – Commencement of Implementation of Using Bar- | |||||||||||||

| coded Disposal Delivery Form (DDF) on 15.1.2005”, Secretary, Public | |||||||||||||

| Fill Committee, Civil Engineering & Development Department. | |||||||||||||

| (y) | Civil Engineering and Development Department Technical Circular No | ||||||||||||

| 05/2005, | Management | of | Construction | and | Demolition | Materials, | |||||||

| Environment, Civil Engineering and Development Department. | |||||||||||||

| (z) | Environmental Permit No. EP-139/2002/A, Environmental Protection | ||||||||||||

| Department | |||||||||||||

Section 5 – Action

5.1 Introduction

Under the Leighton Contractors (Asia) Limited Environmental Management System, waste-management options are categorized in terms of preference from an environmental viewpoint as:

- –

- avoidance and minimization (ie, avoiding or not generating waste through changing or improving processes, practices and design);

That hierarchy is used to evaluate waste-management options, thus allowing maximum waste reduction and often reducing costs. For example, by reducing over-ordering of construction material, waste is avoided and costs are reduced both in terms of purchasing the material and waste disposal.

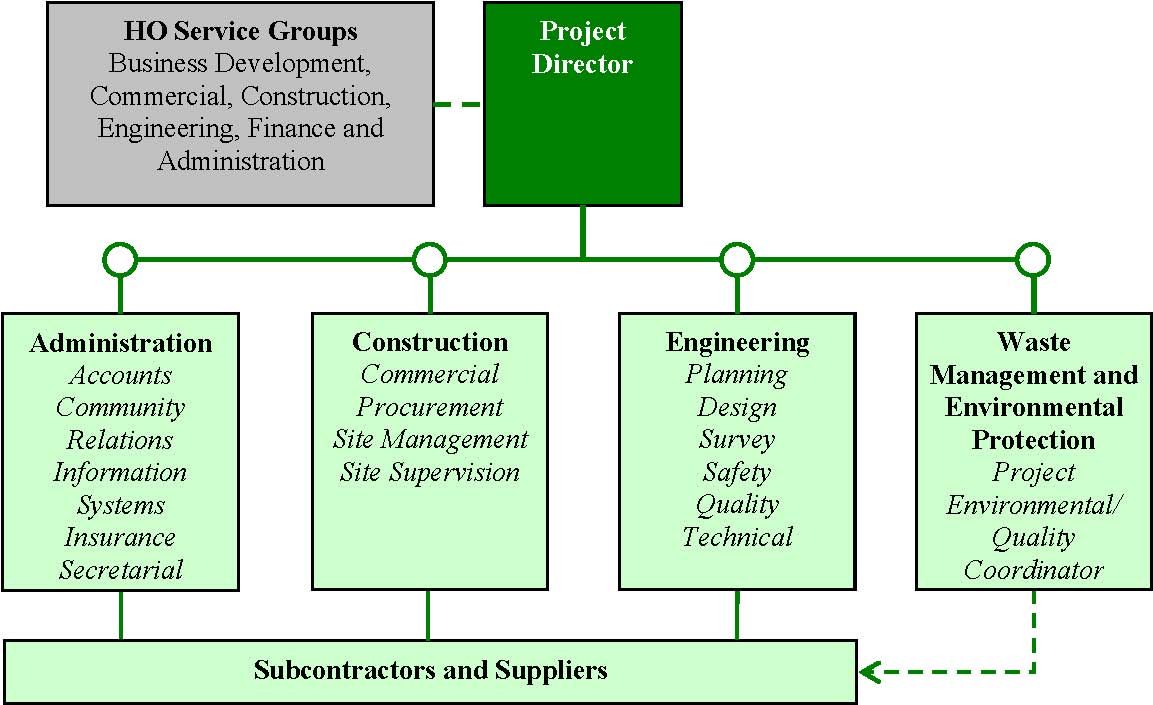

5.2 Organization Structure for Waste Management

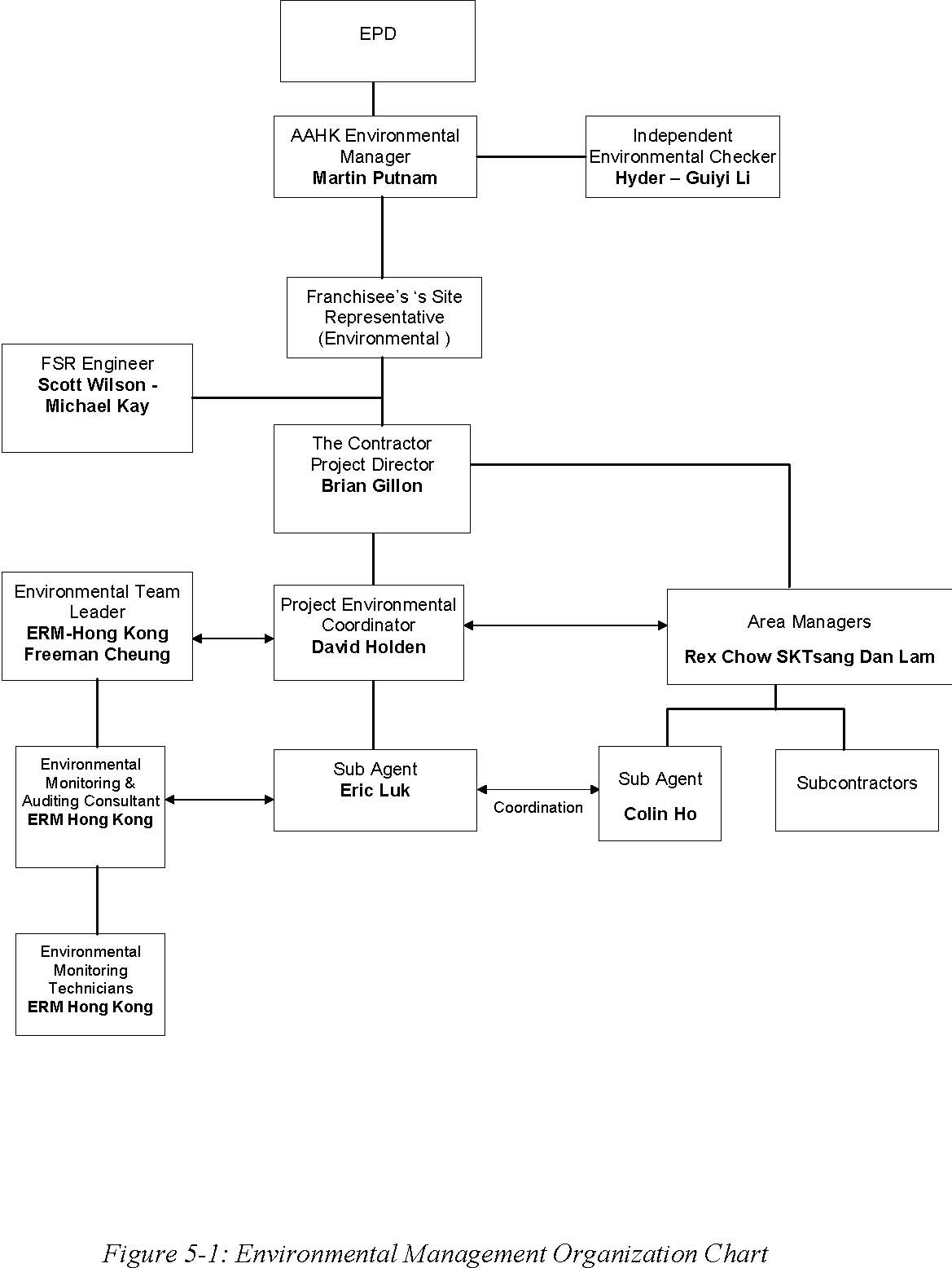

The overall structure of the project organization is maintained separately and identified by the project director for the project. Figure 5-1 shows the arrangement for the organization and lines of communication for waste-management issues.

The project environmental coordinator shall have responsibility for coordinating waste-management activities and initiatives.

5.3 Project Directory

The project secretary maintains a separate project directory that lists details of all key contacts from each of the main organizations participating in the project, including those with responsibility for the implementation of the Waste Management Plan. The directory is made available to project staff by posting on notice boards and/or via the project network (Leighton Asia Document Management System) or similar. The part of the directory relevant to waste management shall be included in Table 5.1 and 5.2 (including subcontractors) and shall include as necessary, names and telephone numbers of work relating to the Waste Management Plan.

Page 13 of 73

H2104-WMP Waste Management Plan: Permanent Aviation Fuel Facility (H2104)

Table 5.1 Waste Management Project Directory

| Name | Position | Organization | Telephone Facsimile E-mail | ||

|---|---|---|---|---|---|

| Brain Gillon | Project director | Leighton Contractors (Asia) Limited | 2403 0900 | 2404 0081 | brian.gillon@leightonas ia.com |

| David Holden | Project Environmental Coordinator | Leighton Contractors (Asia) Limited | 2403 0978 | 2404 0081 | david.holden@leightona sia.com |

| Lewis Cheng | Safety Manager | Leighton Contractors (Asia) Limited | 2403 0921 | 2404 0081 | lewis.cheng@leightonas ia.com |

| Gabriel Ngai | Assistant Safety Officer | Leighton Contractors (Asia) Limited | 2403 0922 | 2404 0081 | gabriel.ngai@leightonas ia.com |

| S K Tsang | Area Manager | Leighton | 2403 0912 | 2404 0081 | sk.tsang@leightonasia.c |

| Contractors | om | ||||

| (Asia) Limited | |||||

| Rex Chow | Area Manager | Leighton | 2403 0909 | 2404 0081 | rex.chow@leightonasis. |

| Contractors | com | ||||

| (Asia) Limited | |||||

| Dan Lam | Area Manager | Leighton | 2403 0908 | 2404 0081 | dan.lam@leightonasia.c |

| Contractors | om | ||||

| (Asia) Limited | |||||

| Tony Hoffman | Superintendent | Leighton Contractors (Asia) Limited | 2404 8900 | 2404 0081 | tony.hoffman@leighton asia.com |

| Eric Luk | Sub Agent | Leighton | 2403 0992 | 2404 0081 | eric.luk@leightonasia.c |

| Contractors | om | ||||

| (Asia) Limited | |||||

| Colin Ho | Sub Agent | Leighton | 2403 0983 | 2404 0081 | colin.ho@leightonasia.c |

| Contractors | om | ||||

| (Asia) Limited | |||||

| Michael Eskridge | Sub Agent | Leighton Contractors (Asia) Limited | 2403 0982 | 2404 0081 | michael.eskridge@leigh tonasia.com |

| Eric So | Senior Engineer | Leighton | 2404 8900 | 2404 0081 | eric.so@leightonasia.co |

| Contractors | m | ||||

| (Asia) Limited | |||||

| Mole Tam | Engineer | Leighton | 2403 0987 | 2404 0081 | mole.tam@leightonasia. |

| Contractors | com | ||||

| (Asia) Limited | |||||

| S L Wu | Senior Engineer | Leighton | 2403 0989 | 2404 0081 | sl.wu@leightonasia.com |

| Contractors | |||||

| (Asia) Limited | |||||

| Edmond Chung | Engineer | Leighton Contractors (Asia) Limited | 2403 0987 | 2404 0081 | edmond.chung@leighto nasia.com |

Page 14 of 73

H2104-WMP Waste Management Plan: Permanent Aviation Fuel Facility (H2104)

| Name | Position | Organization | Telephone | Facsimile | |

|---|---|---|---|---|---|

| Thomas Wong | Senior Engineer | Leighton Contractors (Asia) Limited | 2403 0991 | 2404 0081 | thomas.wong@leighton asia.com |

| Timothy Tse | Engineer | Leighton | 2403 0990 | 2404 0081 | timothy.tse@leightonasi |

| Contractors | a.com | ||||

| (Asia) Limited | |||||

| Billy Chan | Supervisor | Leighton | 2403 0937 | 2404 0081 | |

| Contractors | |||||

| (Asia) Limited | |||||

| Keith Chan | Supervisor | Leighton | 2403 0938 | 2404 0081 | |

| Contractors | |||||

| (Asia) Limited | |||||

| C L Yeung | Foreman | Leighton | 2403 0929 | 2404 0081 | |

| Contractors | |||||

| (Asia) Limited | |||||

| Simon Bennett | Administration Manager | Leighton Contractors (Asia) Limited | 2403 0901 | 2404 0081 | simon.bennett@leighton asia.com |

| Jason Yu | Quantity Surveyor | Leighton | 2403 0901 | 2404 0081 | jason.yu@leightonasia.c |

| Contractors | om | ||||

| (Asia) Limited |

Table 5.2 Subcontractor Details

| Organization | Position | Name | Telephone | Facsimile | |

|---|---|---|---|---|---|

| Hong Kong River | Project | Yu Ming | 6099 0501 | 3150 8332 | yuming007@vip.163.c |

| Eng. Co., Ltd. | Manager | om | |||

| Wing Tat Civil | Site Agent | Simon Chan | 9343 8992 | 2637 2661 | |

| Construction Eng. | |||||

| Ltd. | |||||

| Prosperous Construction Ltd. | Project Manager | Joe Fai | 9093 3966 | 2398 7284 | |

| Union | Project | Raymond | 2459 6199 | 2452 0988 | howaon@i-cable.com |

| Construction Limit | Manager | W.O. Ho |

Project Organization Structure

5.4 Duties and Responsibilities

The primary responsibilities of the project director and project environmental coordinator with respect to the Waste Management Plan and the general responsibilities of project staff are described below.

5.4.1 Project Director

The project director shall:

- –

- be responsible for overall project management and shall have the day-to-day authority and responsibility for time, cost, safety, environmental and quality management;

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

5.4.2 Project Environmental Coordinator

The main duties of the project environmental coordinator are:

- –

- responsibilities:

- -

- monitoring the environmental system on a day-to-day basis to make sure that the requirements of the Environmental Management Plan and Waste Management Plan are operational and effective;

- –

- authority:

- the project environmental coordinator is directly accountable to the Project Director for the implementation and maintenance of the Environmental Management Plan and Waste Management Plan, and for overseeing the monitoring of environmental performance.

5.4.3 Area Managers

The Area Manger has the following duties in relation to waste management control:

- (a)

- Assist the Project Director in implementing the WMP;

5.4.4 Sub Agents / Engineers / Site Supervisors / Foremen

The waste-management responsibilities of the Sub Agents / Engineers / Site

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

Supervisors, Foremen are:

- –

- identify and investigate methods for waste minimization and waste management during planning;

– organize labour, material and equipment to undertake the actions required in the Waste Management Plan.

Other responsibilities relating to the monitoring and measurement of environmental performance and the control and mitigation of environmental impacts are given in the respective Environmental Control Plans in Appendix A and associated checklists that form part of the Waste Management Plan.

5.4.5 Subcontractors

Each subcontractor’s management shall be responsible for making sure that their site personnel are made aware of the environmental mitigation measures required by the Waste Management Plan and that those requirements are implemented to the satisfaction of Leighton Contractors (Asia) Limited. Each subcontractor shall report to the Leighton Contractors (Asia) Limited project director and shall cooperate fully in addressing all environmental matters.

On-site supervisor of each subcontractor shall conduct environmental toolbox talks with respect to waste management to their labourers and workers on a regular basis.

5.4.6 Suppliers

Each supplier shall be responsible for making sure that it complies with any environmental mitigation measures required by the Waste Management Plan. In particular, each supplier shall examine the methods of packaging goods and material to reduce potential future waste whenever practicable and shall consider opportunities for the return/re-use of packaging material.

5.4.7 Manager, Group Systems (Located at Leighton Contractors (Asia) Limited’s Head Office)

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

The manager, group systems is management representative for the Leighton Contractors (Asia) Limited environmental management system. Responsibilities with respect to the implementation of this Waste Management Plan include:

- –

- ensuring that environmental management system requirements are established, implemented and maintained in accordance with ISO 14001;

5.4.8 Environmental Team Leader / Environmental Team, ERM, Hong Kong Ltd. (ETL/ET)

The ETL/ET, ERM Hong Kong, Ltd., shall:

-Review the EIA Report and the detailed designs to ensure that the EIA recommendations and any other measures identified during the reviews are incorporated into the designs;

- Review works programmes, method statements, licence application and other relevant documentation so as to ensure the best practice would be implemented to generate no unacceptable impacts with respect to waste management to the established guidelines/standards;

- Identify any potential unanticipated or greater than expected waste impacts;

- Formulate any necessary preventative or remedial measures to be taken for these potential impacts;

- Liaise with Leighton Contractors (Asia) Limited on waste management regularly and as necessary;

- Carry out complaint investigation, evaluation and identification of preventive and corrective actions

- Undertake environmental site inspection and audit with respect to waste management both regularly and on ad hoc basis at a frequency appropriate to the intensity of the works;

- Liaise and consult with all relevant parties during the implementation of the WMP;

- Address waste management issues in the EM&A Report for submission to the Franchisee Site Representative and Director of Environmental Protection; and

- Report the findings of the site inspections and other environmental performance reviews to IEC and Contractor.

5.4.9 Independent Environmental Checker (IEC), Hyder Consulting Limited

The IEC, Hyder Consulting Limited shall advise the Permit holder (AAHK) on environmental issues related to the project. The role of the IEC shall be independent from the management of construction works; but the IEC shall be empowered to audit the environmental performance of construction.

The main duties of the IEC include the followings:

- Audit the overall waste management programme including the implementation of all waste management mitigation measures and submissions relating to WMP;

- Conduct random site inspection;

- Report the findings of the site inspections and other environmental performance reviews to ECO Fuel Development Ltd. and AAHK; and

- Review and verify the monthly EM&A reports.

5.5 Identification of Potential Waste and Adverse Impacts

The following groups of material are likely to be generated during the construction of the project and their disposal has the potential to cause adverse environmental impacts:

- –

- site-clearance material;

The main activities that have potential to cause adverse environmental impacts from waste include site clearance, utility diversion, excavation works including substructure, manholes, pipeworks and drainage, marine piling works, marine excavation and laying of submarine pipeline, formwork and falsework, concrete works, wet trades and finishing works and fit-out, plant and equipment maintenance and general welfare arrangements for the workforce. The proposed mitigation measures to avoid or minimize the quantity of construction and demolition material generated during the project are described in Section 5.8 and in the control plan for waste and chemical management as detailed in Appendix A.

5.5.1 Site Clearance

Waste material may be generated from site clearance including existing vegetation and trees and surface infrastructure.

5.5.2 Excavated Material

Significant quantities of excavated material will be generated from activities associated with Permanent Aviation Fuel Facility. However, all of this material can be reused on site for purposes such as landscaping or to form bund walls.

5.5.3 Sand Surcharge Material

Significant quantities of sand material will be generated from activities associated with Permanent Aviation Fuel Facility. The majority of this material can be reused on site for purposes such as fill material to excavations and under the tanks. All efforts will be made to ensure that material surplus to requirements will be reused on other contracts.

5.5.4 Dredged Marine Mud

Marine sediment, which is the seabed deposit, is mainly generated from excavation/dredging of sediment/mud. It could be classified as contaminated and uncontaminated based on its contamination level with reference to Chemical Exceedance Level (CEL) laid down in Appendix A of the Environment, Transport and Works Bureau Technical Circular (Works) No 34/2002, Management of Dredged/Excavated Sediment, Environment, Transport and Works Bureau. Significant quantities of marine sediment will be excavated and disposed during the marine pipeline laying works from receiving jetty at Sha Chau to the on-shore Permanent Aviation Fuel Facility at Tuen Mun area.

5.5.5 Construction Waste

Construction waste comprises unwanted material generated during construction, including rejected structures and material, material that has been over ordered or is surplus to requirement and material that has been used and discarded. Waste will arise from a number of site activities throughout the construction period and may include:

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

a) Concrete and Other Cementitious Material

Surplus concrete, concrete debris and cementitious material may result from:

- –

- general in-situ concrete works;

b) Timber

Timber waste may be generated from the fabrication and use of timber formwork.

c) Steel and Other Metallic Waste

The main source of steel waste and other metallic waste is off-cuts resulting from cutting and bending steel reinforcement, steel plates, pipe offcuts and sheet piles for temporary works and E&M fit-out works.

d) General Building Material

The main source of building material waste is surplus bricks, blocks and wall and floor finishes.

5.5.6 Packaging Material

Many types of material and components are delivered to site in cardboard, plastic or timber packaging.

5.5.7 Plastic Waste

The main source of plastic waste is plastic sheets for packaging of material and abandoned sealant cartridge equipment and plastic drink bottles.

5.5.8 Chemical Waste

Chemical waste is generated on site through the maintenance of plant and equipment or following spillage and may include:

- –

- scrap batteries or spent acid/alkali from their maintenance;

Adverse impacts such as land contamination and water pollution will result if material is disposed of incorrectly.

5.5.9 General Refuse

The presence of a construction site with many workers will result in the generation of a variety of general refuse material requiring disposal. General refuse may include food waste, aluminium cans and packing and waste paper.

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

Adverse impacts such as windblown litter, water pollution, odour, hygiene risk and visual impact may occur, together with use of landfill capacity for disposal.

5.6 Estimated Quantities of Waste by Type

The Waste Flow Table included as Appendix B lists the different types of waste stream that are likely to be generated during the works. The Waste Flow Table will be maintained throughout the construction period.

The Waste Flow Table shall be updated on a monthly basis and submitted to the FSR by 1 June and 1 December each year.

According to the Construction and Demolition Material Management Plan, the estimated waste generation pattern is tabulated in the table 5.3 below.

Table 5.3 Estimated waste generation

| Inert construction Waste Category and demolition material for | Natural Excavated Materials, such as fill Waste Type Marine deposit (Type I) | Nil Expected Quantity 274,000 m3 | Disposal Location As allocated by EPD/CEDD (South Cheung | Generation Period Nov 06 – Feb 07 |

|---|---|---|---|---|

| Non-inert construction disposal material for disposal | Site clearance material (eg, trees and vegetation) General refuse Packaging, Plastic | 700 m3 11,000 m3 3,600 kg | WENT Landfill Chau, East Ninepins or East Sha Chau) WENT Landfill WENT Landfill | Dec 05 – Mar 06 Nov 05 – Aug 08 Feb 06 – Aug 08 |

| and demolition material to be re-used or recycled Inert construction | Sand surcharge material Natural Excavated Material, such as fill and rock | 30,032m3 50,922 m3 | On site On site | Nov 05 – May 06 Feb 06 – Jan 08 |

| Sand surcharge material | 10,000m3 | Off site to other contracts via WillPak | Nov 05 – May 06 | |

| Non-inert construction and demolition waste to be recycled/ | Recyclables: Metal / Paper/ Packaging/Timber | 320,000 kg | Engineering Ltd. Paper: Lau Choi Kee Papers co. Other materials to recycling company | Feb 06 – Aug 08 |

| reused on site | soil, trees and vegetation) Site clearance material (e.g., top | 15,000m3 | appointed as necessary On site | 08 Feb 06 – Aug |

| Timber Contaminated soil | 5000kg Nil | The recycling company has to be appointed | Feb 06 – Aug 08 | |

| required licensed disposal Special waste | Chemical waste | 200m3 | Tsing Yi N/A | Feb 06 – Aug 08 N/A |

5.7 Performance Targets

To facilitate assessment of the effectiveness of the waste-management measures, the following performance targets shall be adopted as far as practicable:

- –

- all excavated material will be sorted to recover inert portions (eg, soil and broken rock) for re-use on site or disposal to designated outlets (eg, public filling areas);

5.8 Waste-mitigation Measures

The proposed mitigation measures to avoid or minimize the quantity of construction and demolition material generated during the project are described in the following sections and control plan for waste and chemical management is detailed in Appendix A. The proposed disposal arrangement is also listed and shall be confirmed with CEDD, EPD and FMC in due course.

5.8.1 Site clearance

Site clearance will take place during the execution of activities associated with Permanent Aviation Fuel Facility. Surplus vegetation and organic matter generated shall be stockpiled and used as mulch on the landscape bunds. During site clearance, the relevant requirements of the Construction Dust Regulations shall be adopted.

5.8.2 Demolition Material

Demolition material shall be segregated to maximize possible re-use and recycling. Bituminous material arising from the excavation of existing pavements may be re-used on-site for paving. Inert construction and demolition material may be re-used on site or disposed to public filling Tuen Mun Area 38 fill bank. Other material such as steel shall be recycled as far as practicable. Leighton Contractors (Asia) Limited shall examine further opportunities to use recycled construction and demolition material (eg, from the construction-and-demolition material recycling facility at Tuen Mun Area 38) on the site taking account of the latest available information and the requirements of Works Bureau Technical Circular 12/2002, Specifications Facilitating the Use of Recycled Aggregates.

5.8.3 Surplus Excavated Material

Substantial amount of surplus excavated material will arise from activities associated with Permanent Aviation Fuel Facility. About 50,992 cubic metres of surplus excavated natural material, such as fill material or rock grade IV & V of size less than 200mm, will be made to re-use that material on site or at other sites requiring fill material subject to actual site conditions.

Concrete waste excavated on site shall be sorted and used as armour stone over the pipe line where suitable material is recovered.

An estimated 274,000 cubic metres of Type I marine deposits generated will be disposed of in designated open-sea disposal areas, in accordance with the Particular Specification.

Excavated material shall be segregated from other waste to avoid possible contamination, therefore allowing re-use on site or at other sites that can utilize the material.

5.8.4 Marine Sediment

It is anticipated that about 274,000 m3 (in-situ) material requiring Type 1 open sea disposal.

Dumping permits shall be obtained for the disposal of surplus uncontaminated sediment at the open sea disposal facility.

The management of the marine sediment will be in accordance with the mitigation measures for marine sediment in Appendix A.

5.8.5 Construction Waste Material

The use of prefabricated components shall be considered to reduce the quantity of waste arising from the project. In general, construction waste shall be minimized by carefully planning construction activities to make sure resources are used efficiently and to avoid over ordering. Proper storage and handling procedures shall be used to minimize waste resulting from damage to material.

a) Concrete and Other Cementitious Material

Concrete for both temporary and permanent works shall be delivered to the site in mixer trucks. Depending on access arrangements the concrete shall either be discharged directly from the truck chute or by crane and skip. Concrete delivery shall be controlled to prevent spillage of the concrete. Cleaning out of the truck chute and mixer drum shall be into a designated waste skip or onto plastic sheeting. Waste concrete shall be allowed to harden and then shall be removed from the site.

To minimize waste arising from the use of concrete and other cementitious material, construction activities shall be carefully planned to make sure that resources are used efficiently and that material is not over ordered. When practicable, alternative uses for excess concrete shall also be identified. When disposal is unavoidable, material shall be collected and stored to avoid contamination such that it can be disposed of to a Public Filling Facility.

A target of less than 4.25% of the quantity of concrete waste expressed as a percentage of total quantity delivered have been set for this project to reduce concrete wastage.

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

b) Timber

Waste (e.g. timber from timber formwork/hoarding) arising from temporary works on site can be minimised by alternative forms of design and construction methods. The alternative forms of design and construction methods facilitate not only minimising temporary works and extending their lifespan to reduce waste, but also allowing the use of reusable or recyclable components. Proposed measures to reduce use of timbers in temporary works construction are:-

- (a)

- Consider how the design is constructed to minimise temporary works;

Leighton Contractors (Asia) Limited shall avoid, reduce or minimize the use of timber in temporary works construction as far as possible. Where the Contractor has to use timber for temporary works construction for one process/activity with an estimated quantity exceeding 5m³ or otherwise set by the FSR, he should submit a method statement to the FSR for agreement prior to commencement of the works. The method statement should include the justification for and the measures taken to minimize the use of timber in the temporary works. In addition, the Contractor shall provide a summary table, as attached in Appendix D, containing the description, justification and the estimated quantity for every work process/activity requiring the use of timbers for temporary works irrespective of the quantity of timber used.

Timber formwork shall be carefully dismantled to prevent damage. The timber shall be de-nailed, cleaned and stacked neatly for re-use. Timber hoarding shall not be used and the use of tropical hardwood is prohibited. Wooden pallets for material delivery may be returned to the supplier for re-use.

c) Steel and Other Metallic Waste

Steel waste will come from three main sources: reinforcing steel, steel sheet piles, and offcuts from the storage tank construction. All steel deliveries shall be offloaded using a crane truck. Steel material shall be lifted correctly, stored on timbers and stacked neatly to prevent damage.

Reinforcing steel shall be cut and bent to the approved bar bending schedules. Every effort shall be made to utilize the complete 12-metre length of reinforcing steel bar to minimize off-cuts. Checks shall be made to make sure that the reinforcing steel is cut and bent correctly to prevent errors and the need to scrap

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

incorrectly-bent steel. Off-cuts shall be used to support rebar cages. All surplus steel shall be placed in a skip for recycling.

Steel sheet piles shall be handled correctly to prevent damage. The driving of a sheet pile shall be controlled to ensure maximum utilization of the entire length of the sheet pile. Sheet-pile off-cuts shall be re-used as much as practicable. Scrap sheet piles shall be stacked neatly on timber.

The steel storage tanks contain approximately 4,400 tonne of plate and structural steel, to minimize wastage of steel plate, cutting sheets will be prepared to match the available plate sizes of the supply mill.

Plates steel will be cut and prepared off site where possible. Structural steel for the roof trusses and walkways will be fabricated off site and fixed together on site. Piping isometrics and cutting sheets will be prepared to minimize the amount of off-cut pipework. Plate steel will be delivered to site by barge to minimize handling.

For other metallic waste once identified, recycling companies shall be sought when the quantity and quality of waste makes recycling practicable and cost effective.

d) General Building Material

Good housekeeping measures shall be adopted on site to minimize the quantity of waste that requires disposal. Those measures shall include the allocation of designated storage areas, making sure material is handled carefully by operatives and by implementing a stock management plan.

5.8.7 Packaging Material

The methods of packaging goods and material shall be examined with suppliers when placing orders to minimize potential future waste.

Packaging material may be returned to the supplier when that service is offered. Alternatively, efforts shall be made to identify and utilize companies that are prepared to accept packaging material of the quality and quantity produced by the site for recycling purposes. That material shall be segregated and removed from site periodically.

5.8.8 Plastic Waste

The mitigation measures identified in Appendix A shall apply to plastic sheets for packaging of material and equipment.

Plastic drink bottles shall be segregated and collected for recycling purposes.

5.8.9 Chemical Waste

Chemical waste shall be disposed in accordance with statutory requirements. The project site shall register as a chemical waste producer with the Environmental

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

Protection Department and shall establish suitable temporary storage facilities for that waste at the site. Those facilities and methods shall comply with the Code of Practice on the Packaging, Labelling and Storage of Chemical Wastes.

Containers used for the storage of chemical waste (mainly spent lubricating oil)

shall:

- (a)

- be suitable for the substance they are holding, resistant to corrosion, maintained in a good condition, and securely closed;

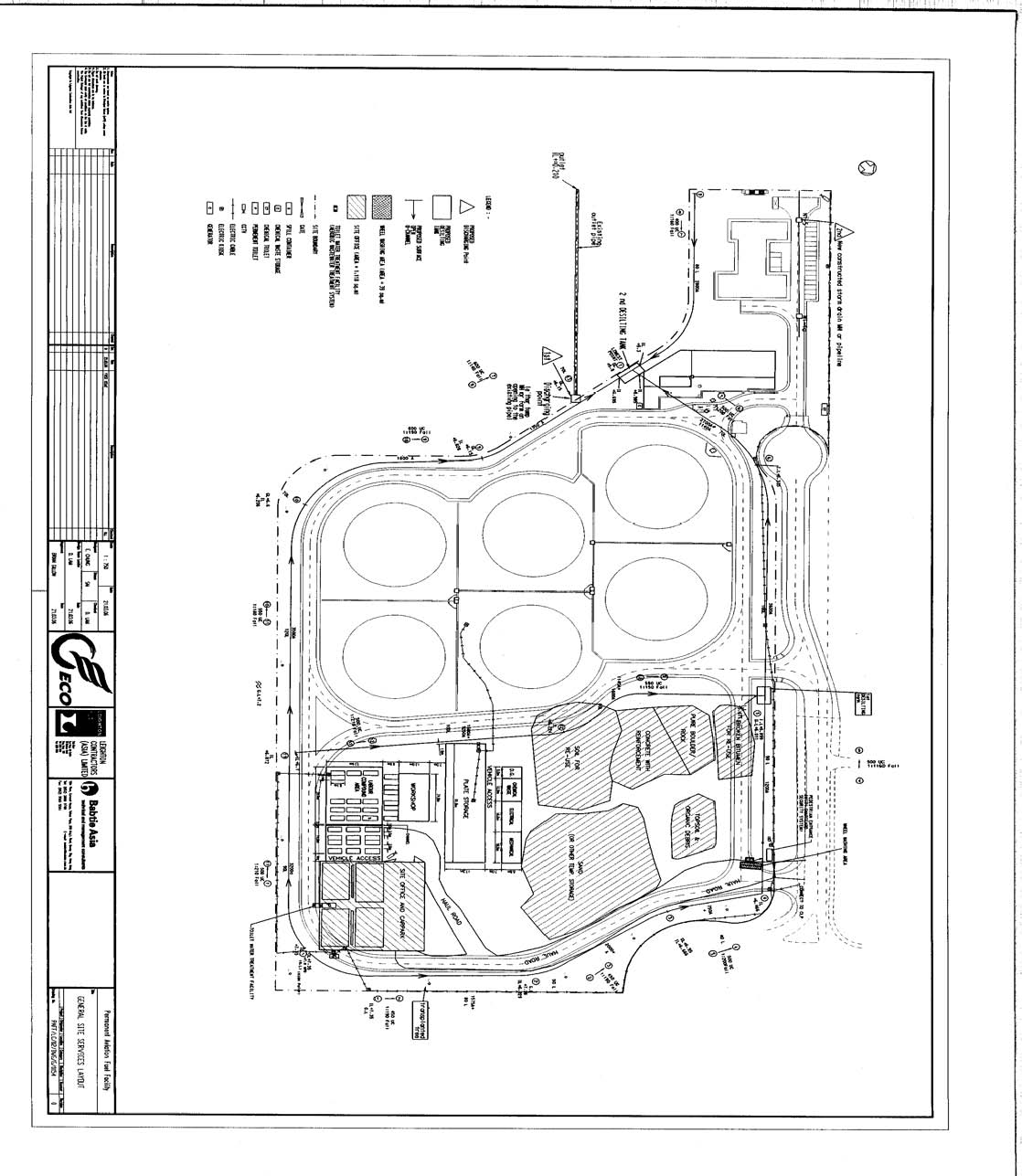

The storage area for chemical wastes, as shown in Figure 5-2, shall:

- (a)

- be clearly labelled and used solely for the storage of chemical waste;

Disposal of chemical waste shall:

- (a)

- be via a licensed waste collector; and

Trip tickets for disposal shall be retained. Other hazardous material used on site shall be stored to minimize the risk of land contamination or water pollution. Measures shall typically include the use of bunded areas for bulk storage and drip trays or impermeable sheeting covered by absorbent material to collect accidental spillage.

The environmental emergency procedures as shown in appendix E shall be implemented to deal with any accidental spillage of chemicals on site.

5.8.10 General Refuse

General refuse generated on-site shall be stored in bins or skips separate from construction and chemical wastes. General refuse shall be removed frequently to

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

minimize odour, pest and litter impacts and shall be disposed to strategic landfill. The burning of refuse on-site is prohibited.

Measures that encourage waste avoidance/minimisation include:

| (a) | Reducing the number of photo copies to a minimum and by copying on |

| both sides of paper for internal documents and external documents where | |

| appropriate; | |

| (b) | Preventing over-ordering of office equipment and consumables; |

| (c) | Procuring green office equipment and consumables in terms of energy |

| efficiency, recycled content and durability, etc; | |

| (d) | Providing drinking facility and encouraging employees to bring their own |

| cup; and | |

| (e) | Discouraging take-out food. |

Additional measures that facilitate reuse/recycling and orderly disposal include:

- (a)

- Deploying sufficient refuse collection bin at convenient locations to facilitate collection of non-recyclables for disposal at landfills;

5.8.11 Disposal of Public Fill

Drivers shall be instructed to make sure that their trucks are not overloaded. Visual checks shall be undertaken by site security to make sure trucks are loaded within legal limits and suitably covered.

5.8.12 Disposal of Construction and Demolition Waste to Landfill

When construction and demolition waste cannot be re-used or recycled, it shall be disposed at the approved strategic landfill site.

5.8.13 Site Tidiness

The site shall be kept in a tidy manner at all times. The site establishment shall be planned with areas allocated for containers, plant, storage of material and waste skips. Direct and subcontract labour shall be responsible for making sure that the site is kept in a tidy manner. All labour involved on the site shall be responsible for making sure that tools are cleaned and put away, equipment is stored away after use, and un-used material is neatly stacked or stored in areas provided. All areas of the site shall be kept clean and tidy, access/egress points shall be swept, and passageways shall be kept free from material and plant or equipment. Waste material shall be stored in the receptacles provided, which shall be emptied regularly.

5.9 Site Cleanliness

The measures listed below for the improvement of site cleanliness and to control

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

mosquito breeding on construction sites shall be implemented.

- –

- the project environmental coordinator shall be responsible for the overall coordination, monitoring and overseeing of the performance of the site on cleanliness;

5.10 Waste Management Plan Implementation

5.10.1 Training and Awareness

As part of Leighton Contractors (Asia) Limited’s Environmental Management System, training to address waste-management issues shall be conducted for all Leighton Contractors (Asia) Limited staff, subcontractors and the general workforce. That training may take the form of environmental induction training, tool-box meetings or similar and shall be carried out in accordance with the requirements of the Project Environmental Plan. In addition, waste-management coordination meetings shall be held as necessary. The environmental training programme for Permanent Aviation Fuel Facility is shown below in table 5.4.

Arrangement shall be made for the project director, project environmental coordinator and other key site personnel to attend training on waste management if they have not previously attended similar courses.

Table 5.4 Training Programme

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

Page 31 of 73

H2104-WMP Waste Management Plan: Permanent Aviation Fuel Facility (H2104)

| Details of Training | Training Recipients | Trainer / Presenter | Target Date | Frequency |

|---|---|---|---|---|

| Detailed review of the | Project environmental | Manager, | December | Once |

| Construction Environmental | coordinator | Group | 2005 | |

| Management Plan and | Systems or | |||

| associated procedures | nominee | |||

| Introduction to the | All project staff | Manager, | December 05 | Once, |

| Environmental Management | Group | / January 06 | refresher | |

| System and overview of | Systems or | training | ||

| policy and documentation | nominee | provided on a | ||

| needs basis | ||||

| General Environmental | All project staff | Project | December 05 | Periodic as |

| Awareness Training, | environmental | and ongoing | needs dictate | |

| including the project’s | coordinator/ | |||

| significant environmental | manager, | |||

| aspects | group | |||

| systems | ||||

| Specific training in the | Appropriate staff | Project | As required | Dependent on |

| operation of the | environmental | identified | ||

| Environmental Management | coordinator | training needs | ||

| Plan and Waste Management | ||||

| Plan and environmental | ||||

| mitigation controls | ||||

| Induction to environmental | All workers | Project | Before | Once |

| issues relevant to the | environmental | commencing | ||

| workforce | coordinator/sa | work on-site | ||

| fety officer | ||||

| Tool-box talks introducing | Workforce | Project | Ongoing | Monthly basis |

| environmental issues | environmental | |||

| coordinator/sa | ||||

| fety officer |

5.10.2 Segregation

Preliminary sorting of the waste generated from various construction activities as detailed in Section 5.5 shall be conducted on site into distinct categories based on their composition.

During site planning stage, waste facilities shall be designed and established to facilitate on-site sorting of C&D materials, collection of recyclable materials by recycling companies, and collection of non-recyclable materials by waste haulers. Proposed types of waste facilities and collection frequency are given in Table 5.5 below.

Table 5.5 Proposed Types of Waste Facilities

| Waste skip Waste Facility Refuse collection bin Chemical waste store Chemical toilet | C&D waste, general refuse Waste Type(s) General refuse (i.e. non-recyclable materials) Chemical waste such as spent lubricating oil Toilet waste | Once the skip is filled. Collection Frequency* Once the bin is filled. Once the container is filled Two days per week (chemical toilet) |

|---|

Page 32 of 73

H2104-WMP Waste Management Plan: Permanent Aviation Fuel Facility (H2104)

Temporary

Inert C&D hard and soft

Once the temporary

sorting/storage/

materials, scrap metals and

sorting/storage/stockpiling

stockpiling area

reclaimed asphalt pavement

areas are filled

(RAP)

*Collection frequency shall be reviewed based on the actual storage capacity of the waste facilities and minimum collection frequency may be required apart from stipulating collection only when the bin is full.

Surplus construction-and-demolition material shall be sorted on site into inert and non-inert material for disposal. Inert construction-and-demolition material shall be segregated on-site in order to maximize the recovery of re-usable and recyclable material. A system of work for on-site sorting shall be included to identify the source of generation, estimated quantity, arrangement for on-site sorting and collection, temporary storage areas, frequency of collection by recycling contractors or frequency of removal off-site. Consideration shall be taken to sort inert construction and demolition material at source to avoid double handling as far as practicable. Except for re-usable inert construction-and-demolition material, all other inert construction-and-demolition material shall be broken down into manageable size and removed off-site as soon as practicable to optimize the use of the on-site storage space.

As far as practicable, general refuse shall be segregated at source by the use of bins for different types of material.

5.10.3 Recycling

Arrangements shall be made with potential recycling contractors so that recyclable material sorted from the site is collected with reasonable care. The quantities of recyclable material shall be recorded before removal off site by the designated recycling contractor and details shall be included in the Waste Flow Table.

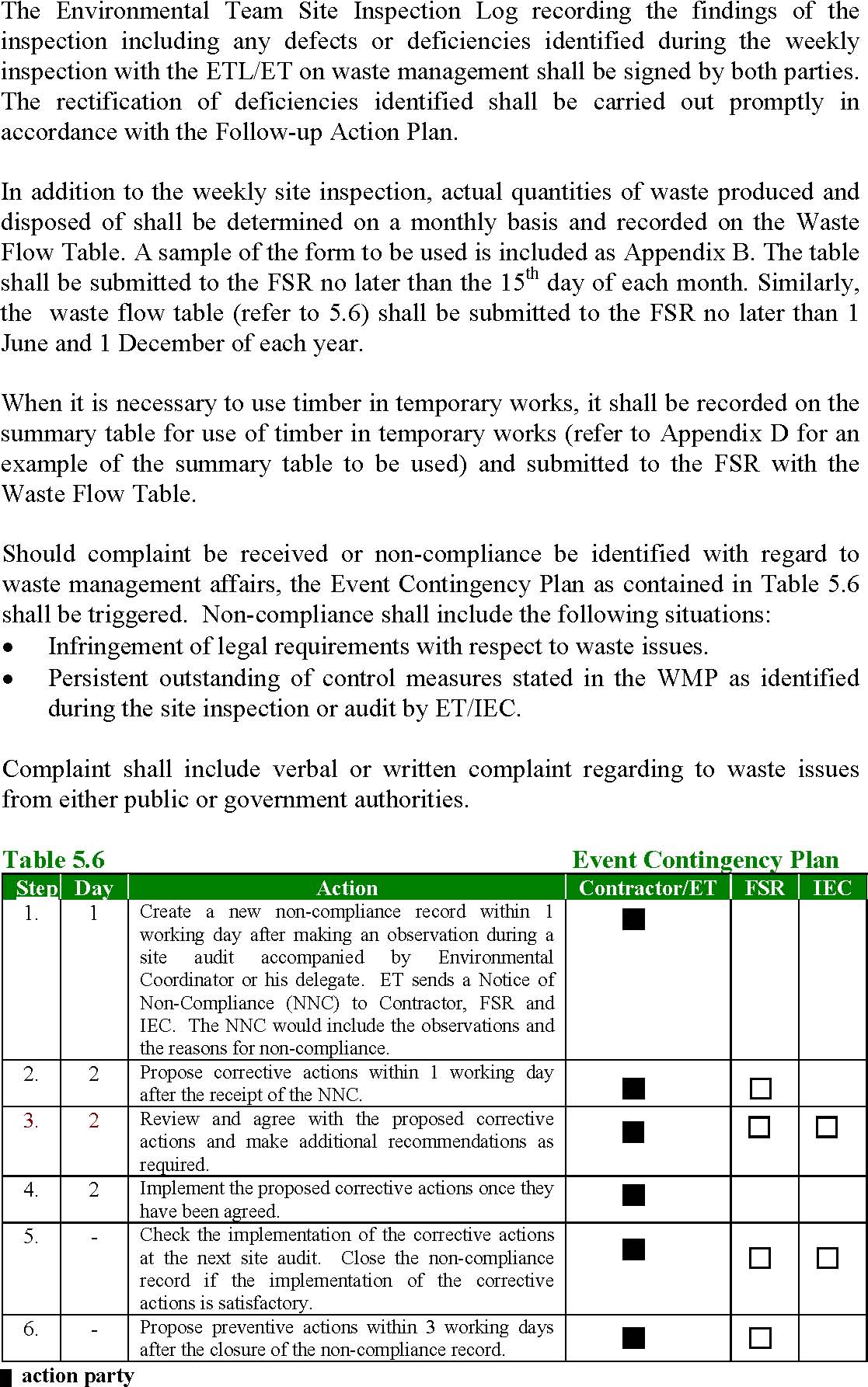

5.10.4 Monitoring and Reporting

Regular inspection shall be carried out by area managers and the project environmental coordinator to inspect the site to make sure that performance is satisfactory and complies with the Waste Management Plan.

A comprehensive checklist, as shown in Appendix C, for use during the weekly inspection shall be used. The defects or deficiencies identified during the weekly inspection on waste management, together with their respective locations and the agreed due dates for rectification, shall be entered in a summary table of follow-up actions. The summary table of follow-up actions shall be agreed and signed by the project environmental coordinator and a copy shall be provided to relevant project staff. Rectification of the deficiencies identified shall be carried out promptly in accordance with the Follow-up Action Plan.

Regular inspection will also be carried out by area managers, the project environmental coordinator and the ETL/ET to inspect the site to make sure that performance is satisfactory and complies with the Waste Management Plan as per the requirements of the EM & A Manual.

![]() comments on the non-compliance record where applicable.

comments on the non-compliance record where applicable.

ET – Contractor’s Environmental Team; IEC – Independent Environmental Checker; FSR – Franchisee’s Site Representative

5.10.5 Audit

The Environmental Management System is subject to regular audits by the manager, group systems. The results of those audits are reported to directors and senior management via regular environmental management committee meetings.

The project shall also be subject to third-party audits carried out by the Hong Kong Quality Assurance Agency to check compliance with the ISO 14001 standard.

5.10.6 Records

All environmental records (eg, delivery dockets, trip tickets, estimates of waste quantities, photographs and measurement records) generated during implementation of the Waste Management Plan shall be placed in the project filing system. Trip tickets shall be maintained for the disposal of chemical waste.

Copies of the Monthly and Yearly Summary Waste Flow Table together with the summary table for work process or activities requiring timber for temporary works shall be maintained.

5.10.7 Performance Monitoring

The following items shall be included in the agenda for discussion at every project environmental review committee meeting, or other agreed established channels for performance monitoring:

- –

- review the Waste Management Plan; including the quantities and types of construction and demolition material generated, re-used and disposed off-site; the amount of fill material imported to the site and quantity of timber used in temporary works for each construction process/activity;

5.11 Conclusion

Construction and demolition waste, chemical waste and general refuse arising from construction activities shall be managed in accordance with the proposed mitigation measures and statutory requirements. Each waste stream shall be kept segregated whenever practicable to avoid cross-contamination allowing inert construction waste to be re-used as far as practicable or disposed of at public filling facilities, thereby minimizing the need for disposal to strategic landfill.

The Waste Management Plan for the project shall be incorporated within the framework of the Leighton Contractors (Asia) Limited Management System. The system shall set out the operational and monitoring requirements to ensure successful implementation.

Section 6 – Glossary of Terms

C&D material

Construction-and-demolition material for disposal that contains a mixture of inert and non-inert material. The inert portion is known as public fill and comprises excavated earth, asphalt, building debris, broken rock and concrete. The non-inert portion is classified as construction-and-demolition waste (see below).

C&D waste

Construction-and-demolition waste is material that is not accepted for disposal at public filling facilities. That material may include marine mud, household refuse, plastic, metal and chemical waste, vegetable material and other unsuitable material.

chemical waste

Any substance or thing being scrap material, effluent or an unwanted substance or by-product arising from the application of or in the course of producing any substance or chemical specified in Schedule 1 of the Waste Disposal (Chemical Waste) (General) Regulation if such substance or chemical occurs in such form, quantity and concentration so as to cause pollution or constitute a danger to health or risk of pollution to the environment.

landfill

A strategically-located waste-disposal area that accepts construction and demolition waste.

PEC

Project environmental coordinator – a generic term for the environmental management representative at the project office.

public filling facility

Public filling facilities are managed by the Civil Engineering and Development Department and include:

- –

- public-filling areas (usually a designated part of a development project that accepts public fill for reclamation purposes);

public fill stockpile area

A newly-reclaimed land area where public fill is stockpiled as surcharging material to accelerate the settlement process. It also may be used to stockpile material for reprocessing and re-use (eg, as recycled aggregate).

Public Fill Committee

The Public Fill Committee has the responsibility to implement measures to promote avoidance, minimization, re-use and recycling of construction and demolition material. It also oversees the management of public-filling operations and facilities and the use of land-based fill reserves. In addition, the Public Fill Committee produces and circulates

Leighton Contractors (Asia) Limited Revision 2 03.04.2006

Paper copies are uncontrolled. The controlled version is on the Project Server

the Public Filling Programme and designates the public-filling facilities for public-works projects.

FSR

Franchisee’s Site Representative

Client

ECO Aviation Fuel Development Ltd.

Client’s Representative

The Person named by ECO Aviation Fuel Development

ETL / ET

Environmental Team Leader / Environmental Team, ERM, Hong Kong Ltd.

IEC

Independent Environmental Checker, Hyder Consulting Limited

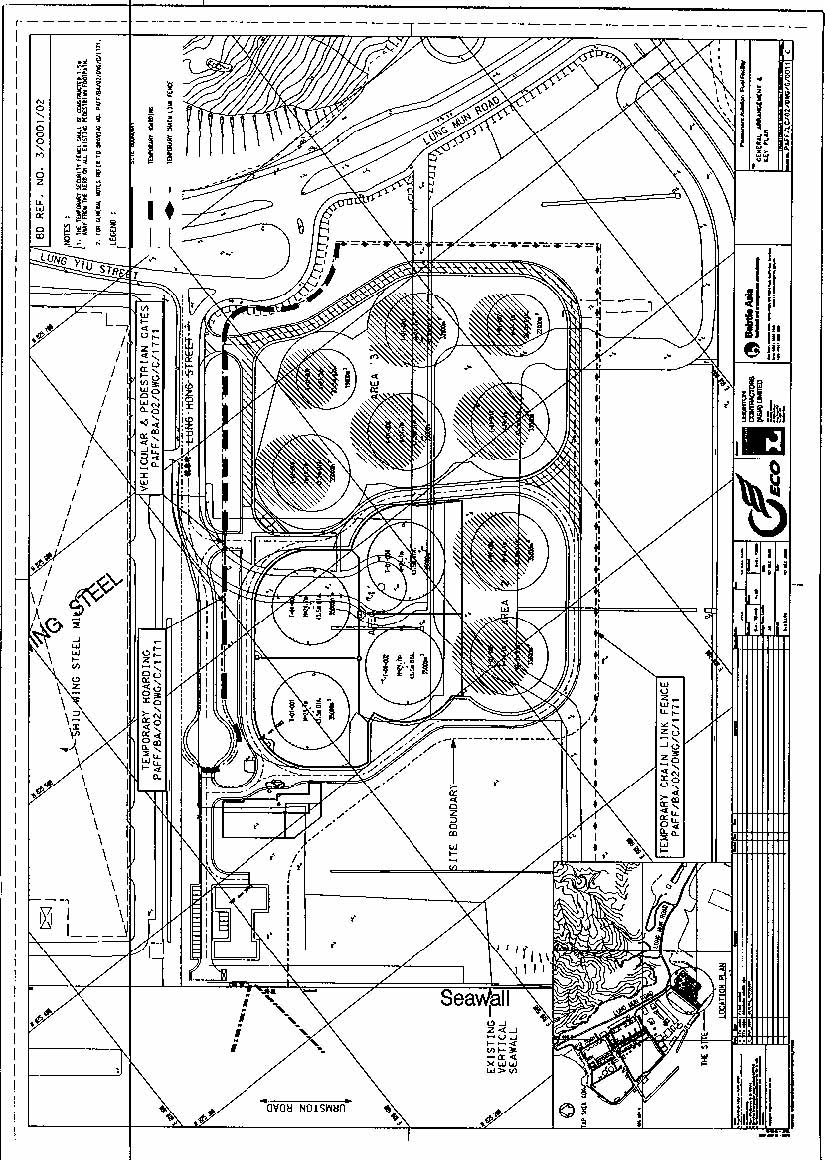

Figure 2-1: General Location Plan

H2104-WMP Waste Management Plan:

Permanent Aviation Fuel Facility (H2104)

Figure 5-2: Location Plan for Waste Facilities and Stockpiling Areas

Appendix A Environmental Control Plan ECP 5 – Waste and Chemical Management

Permanent Aviation Fuel Facility Waste Management Plan

| Environmental Control Plan | LEIGHTON | ||||||

|---|---|---|---|---|---|---|---|

| Contract Name: Permanent Aviation Fuel Facility | Plan No. | ECP 5 | |||||

| Environmental Aspect: Waste and Chemical Management | Contract No: H2104 | ||||||

| Item | Required Mitigation Measures and Operational Controls | Objectives of Measures (concerns to address) | Action by | Location and Activity | Frequency or Duration | Performance Standard to be Achieved | |

| Storage, Collection and Transportation | |||||||

| 1 | Handle and store waste in a manner that ensures that it is held securely without loss or leakage Establish separate waste bins for construction waste, general refuse and recyclables on-site and have their locations labelled on the site-layout plan | Minimize the potential for pollution (Contract compliance) | Area Managers | All construction sites | Construction stage | Different waste stream are handled and stored in accordance with site-layout plan and Waste Management Plan | |

| 2 | Use waste collectors authorized or licensed to collect the specific category of waste Only engage licensed waste collectors during the procurement phase | Waste disposal control (Contract compliance) | Area Managers | All construction sites | Construction stage | Waste collectors authorized and licensed by Environmental Protection Department | |

| 3 | Remove waste in a timely manner Allocate staff to monitor capacity of storage facilities and contact licensed waste collectors for collection, include check item on routine environmental checklist | Waste management and housekeeping (Prevent visual impacts and hygiene concerns) | Area Managers | All construction sites | Construction stage | Adequate capacity for workforce activities | |

© Leighton Contractors (Asia) Limited, 2005 Page 42 of 73 H2104 WMP; Revision 2; 03.04.06. Permanent Aviation Fuel Facility Waste Management Plan

| Environmental Control Plan | LEIGHTON | ||||||

|---|---|---|---|---|---|---|---|

| Contract Name: Permanent Aviation Fuel Facility | Plan No. | ECP 5 | |||||

| Environmental Aspect: Waste and Chemical Management | Contract No: H2104 | ||||||

| Item | Required Mitigation Measures and Operational Controls | Objectives of Measures (concerns to address) | Action by | Location and Activity | Frequency or Duration | Performance Standard to be Achieved | |

| 4 | Maintain and clean waste storage areas | Waste management | Area Managers | All construction | Construction stage | Maintained and | |

| regularly | and housekeeping to | sites | cleaned in | ||||

| Establish maintenance schedule, allocate labour to carry out routine maintenance and cleaning | prevent visual impacts and hygiene concerns | accordance with maintenance schedule | |||||

| (Contract | |||||||

| compliance) | |||||||

| 5 | Minimize wind-blown litter and dust | Prevention of public | Area Managers | All construction | Construction stage | Visual check by gate | |

| during transportation by either covering trucks or transporting wastes in an enclosed container Secure cover prior to leaving and make | road contamination (Contract compliance) | sites | attendant or other assigned personnel | ||||

| sure truck is not overloaded | |||||||

| 6 | Obtain the necessary waste-disposal permits from the appropriate authorities, if they are required, in accordance with the Waste Disposal Ordinance (Cap 354), Waste Disposal (Chemical Waste) (General) Regulation (Cap 354) and the Land (Miscellaneous Provisions) Ordinance (Cap 28) | Prevention of uncontrolled waste disposal (Legal compliance) | Area Managers | All construction sites | Construction stage | Waste disposal permits issued by appropriate authorities | |

| Apply well in advance of disposal activities | |||||||

© Leighton Contractors (Asia) Limited, 2005 Page 43 of 73 H2104 WMP; Revision 2; 03.04.06. Permanent Aviation Fuel Facility Waste Management Plan

| Environmental Control Plan | LEIGHTON | ||||||

|---|---|---|---|---|---|---|---|

| Contract Name: Permanent Aviation Fuel Facility | Plan No. | ECP 5 | |||||

| Environmental Aspect: Waste and Chemical Management | Contract No: H2104 | ||||||

| Item | Required Mitigation Measures and Operational Controls | Objectives of Measures (concerns to address) | Action by | Location and Activity | Frequency or Duration | Performance Standard to be Achieved | |

| 7 | Dispose of waste at licensed sites Engage licensed waste collectors for disposal, incorporate trip-ticket system | Prevention of uncontrolled waste disposal (Legal compliance) | Area Managers | All construction sites | Construction stage | In accordance with permit conditions, record of signed and chopped trip tickets | |

| 8 | Develop procedures, such as a ticketing system, to facilitate tracking of loads, particularly for chemical waste, and to ensure that illegal disposal of waste does not occur Set up trip ticket system in accordance with requirements set out in ETWB TC 31/2004, issue trip ticket for each truck load of waste being transported off site | Prevention of uncontrolled waste disposal (Legal compliance) | Area Managers | All construction sites | Construction stage | Signed and chopped trip tickets returned for each truckload of waste, in accordance with Waste Management Plan | |

| 9 | Maintain records of the quantities of wastes generated, recycled and disposed Establish waste flow tables at Contract start and keep them maintained and updated throughout the Contract period | Waste management | Area Managers | All construction sites | Construction stage | Waste flow tables updated at least on a monthly basis, in accordance with Waste Management Plan | |

| Contaminated Soil and Marine Deposit | |||||||

| 1 | Uncontaminated marine deposits shall require open-sea disposal Engage licensed waste collectors, incorporate trip-ticket system | Waste disposal control (Legal and contractual compliance) | Area Managers | All construction sites | Construction stage | Record of signed and chopped trip tickets | |

© Leighton Contractors (Asia) Limited, 2005 Page 44 of 73 H2104 WMP; Revision 2; 03.04.06. Permanent Aviation Fuel Facility Waste Management Plan

| Environmental Control Plan | LEIGHTON | ||||||

|---|---|---|---|---|---|---|---|

| Contract Name: Permanent Aviation Fuel Facility | Plan No. | ECP 5 | |||||

| Environmental Aspect: Waste and Chemical Management | Contract No: H2104 | ||||||

| Item | Required Mitigation Measures and Operational Controls | Objectives of Measures (concerns to address) | Action by | Location and Activity | Frequency or Duration | Performance Standard to be Achieved | |

| 2 | During the handling of contaminated/uncontaminated marine sediment, all construction plant and equipment shall be designed and maintained to minimize the risk of silt, | Prevention of uncontrolled release of waste material | Area Managers | All construction sites | Construction stage | Construction plant and equipment maintained in accordance with maintenance | |

| sediments, contaminants or other | schedule, maintain | ||||||

| pollutants being released into the water column or deposited in the locations other than designated location | plant and equipment in designated area (eg, workshop) only | ||||||

| Establish maintenance schedule, collect | |||||||

| and treat cleaning water from plant maintenance prior to discharge | |||||||

| 3 | During the handling of contaminated/uncontaminated marine sediment, size all vessels such that adequate draft is maintained between vessels and the sea bed at all states of the | Prevention of contaminated deposit from releasing into the water column | Area Managers | Barging point | Construction stage | Adequate clearance to seabed as appropriate | |

| tide to ensure that undue turbidity is not generated by turbulence from vessel movement or propeller wash | |||||||

| Select vessel taking account of sea-bed profile | |||||||

© Leighton Contractors (Asia) Limited, 2005 Page 45 of 73 H2104 WMP; Revision 2; 03.04.06. Permanent Aviation Fuel Facility Waste Management Plan

| Environmental Control Plan | LEIGHTON | ||||||

|---|---|---|---|---|---|---|---|

| Contract Name: Permanent Aviation Fuel Facility | Plan No. | ECP 5 | |||||

| Environmental Aspect: Waste and Chemical Management | Contract No: H2104 | ||||||

| Item | Required Mitigation Measures and Operational Controls | Objectives of Measures (concerns to address) | Action by | Location and Activity | Frequency or Duration | Performance Standard to be Achieved | |

| 4 | During the handling of contaminated/uncontaminated marine sediment and before moving the vessels that are used for transporting dredged material, clean excess material from the | Prevention of dredged material from releasing into the water column | Area Managers | Barging point | Construction stage | No visible excess material on deck and exposed fittings of vessels | |

| decks and exposed fittings of vessels and the excess material shall never be | |||||||

| dumped into the sea except at the approved locations | |||||||

| Allocate labour to clean using brush, shovel or similar and place excess material back onboard of vessels | |||||||

| 5 | During the handling of contaminated/uncontaminated marine sediment, maintain adequate freeboard to ensure that decks are not washed by wave action | Prevention of uncontrolled release of waste material | Area Managers | Barging point / sediment handling | Construction stage | Adequate freeboard as appropriate | |

| Ensure vessels are not overloaded at all | |||||||

| time | |||||||

© Leighton Contractors (Asia) Limited, 2005 Page 46 of 73 H2104 WMP; Revision 2; 03.04.06. Permanent Aviation Fuel Facility Waste Management Plan

| Environmental Control Plan | LEIGHTON | ||||||

|---|---|---|---|---|---|---|---|

| Contract Name: Permanent Aviation Fuel Facility | Plan No. | ECP 5 | |||||

| Environmental Aspect: Waste and Chemical Management | Contract No: H2104 | ||||||

| Item | Required Mitigation Measures and Operational Controls | Objectives of Measures (concerns to address) | Action by | Location and Activity | Frequency or Duration | Performance Standard to be Achieved | |

| 6 | During the handling of contaminated/uncontaminated marine | Prevention of uncontrolled waste | Area Managers | Barging point / sediment handling | Construction stage | Logs and records of all vessels movement | |

| sediment, monitor all vessels transporting material to ensure that no dumping outside the approved location takes place. Logs and other records shall | disposal (Legal compliance) | transporting material for disposal | |||||

| be kept and produced to demonstrate compliance and that journeys are | |||||||

| consistent with designated locations and copies of such records shall be submitted | |||||||

| to the Engineer | |||||||

| 7 | During the handling of | Prevention of | Area Managers | Barging point / | Construction stage | No breach of license | |

| contaminated/uncontaminated marine sediment, comply with the conditions in | uncontrolled waste disposal | sediment handling | condition | ||||

| the Dumping Licence | (Legal compliance) | ||||||

| 8 | During the handling of contaminated/uncontaminated marine | Prevention of uncontrolled release | Area Managers | Barging point / sediment handling | Construction stage | Tightness checked in accordance with | |

| sediment, fit all bottom-dumping vessels (hopper barges) with tight fittings seals | of waste material | maintenance schedule | |||||

| to their bottom openings to prevent leakage of material | |||||||

| 9 | During the handling of contaminated/uncontaminated marine | Prevention of uncontrolled release | Area Managers | Barging point / sediment handling | Construction stage | No adverse impacts or complaints | |

| sediment, place the material into the disposal pit by bottom dumping. | of waste material | ||||||

© Leighton Contractors (Asia) Limited, 2005 Page 47 of 73 H2104 WMP; Revision 2; 03.04.06. Permanent Aviation Fuel Facility Waste Management Plan

| Environmental Control Plan | LEIGHTON | ||||||

|---|---|---|---|---|---|---|---|

| Contract Name: Permanent Aviation Fuel Facility | Plan No. | ECP 5 | |||||

| Environmental Aspect: Waste and Chemical Management | Contract No: H2104 | ||||||

| Item | Required Mitigation Measures and Operational Controls | Objectives of Measures (concerns to address) | Action by | Location and Activity | Frequency or Duration | Performance Standard to be Achieved | |

| 10 | During the handling of contaminated/uncontaminated marine | Prevention of uncontrolled release | Area Managers | Barging point | Construction stage | Barge-type approved | |

| sediment, transport contaminated marine mud by split barge of not less than 750 m3 capacity and capable of rapid opening | of waste material | ||||||

| and discharge at the disposal site | |||||||

| 11 | During the handling of contaminated/uncontaminated marine | Prevention of uncontrolled release | Area Managers | Dumping pit | Construction stage | No adverse impacts or complaints | |

| sediment, discharge shall be undertaken rapidly and the hoppers shall be closed | of waste material | ||||||

| immediately | |||||||

| 12 | During the handling of contaminated/uncontaminated marine sediment, material adhering to the sides of the hopper shall not be washed out of the hopper and the hopper shall remain closed until the barge returns to the disposal site | Prevention of uncontrolled release of waste material | Area Managers | Barging point | Construction stage | No adverse impacts or complaints | |

| Clean using brush, shovel or similar and place material back onboard of vessels | |||||||

© Leighton Contractors (Asia) Limited, 2005 Page 48 of 73 H2104 WMP; Revision 2; 03.04.06. Permanent Aviation Fuel Facility Waste Management Plan

| Environmental Control Plan | LEIGHTON | ||||||

|---|---|---|---|---|---|---|---|

| Contract Name: Permanent Aviation Fuel Facility | Plan No. | ECP 5 | |||||

| Environmental Aspect: Waste and Chemical Management | Contract No: H2104 | ||||||

| Item | Required Mitigation Measures and Operational Controls | Objectives of Measures (concerns to address) | Action by | Location and Activity | Frequency or Duration | Performance Standard to be Achieved | |

| Construction and Demolition Material | |||||||

| 1 | Opportunity for re-using of fill material for back-filling should be optimized Investigate opportunity to re-use fill material at Permanent Aviation Fuel | Waste management, minimize disposal of material | Area Managers | All construction sites | Construction stage | Quantities of fill material re-used exceed original anticipation | |

| Facility and other projects at Contract start and review proposal periodically. Temporarily stockpile re-usable fill material on-site with appropriate protective measures (eg, cover with impervious sheeting) | |||||||

| 2 | Transport excavated material that cannot be recycled to public filling areas | Prevention of uncontrolled waste | Area Managers | All construction sites | Construction stage | Record of signed and chopped trip tickets | |

| Engage licensed waste collectors, incorporate trip-ticket system | disposal (Legal compliance) | ||||||

| 3 | Careful design, planning and good site | Prevention of | Area Managers / | All construction | Construction stage | Minimize wastage | |

| management to minimize over-ordering and waste material such as concrete, | generation of waste | Quantity Surveyor | sites | ||||

| mortar and cement grout | |||||||

| 4 | The design of formwork shall maximize the use of standard wooden panels so that high re-use levels can be achieved. Alternatives such as steel formwork or | Prevention of generation of waste by using recyclable material | Area Managers / Design Engineer | All construction sites | Construction stage | Approved design by ECO Aviation Fuel Development Ltd. | |